The Linotype Machine

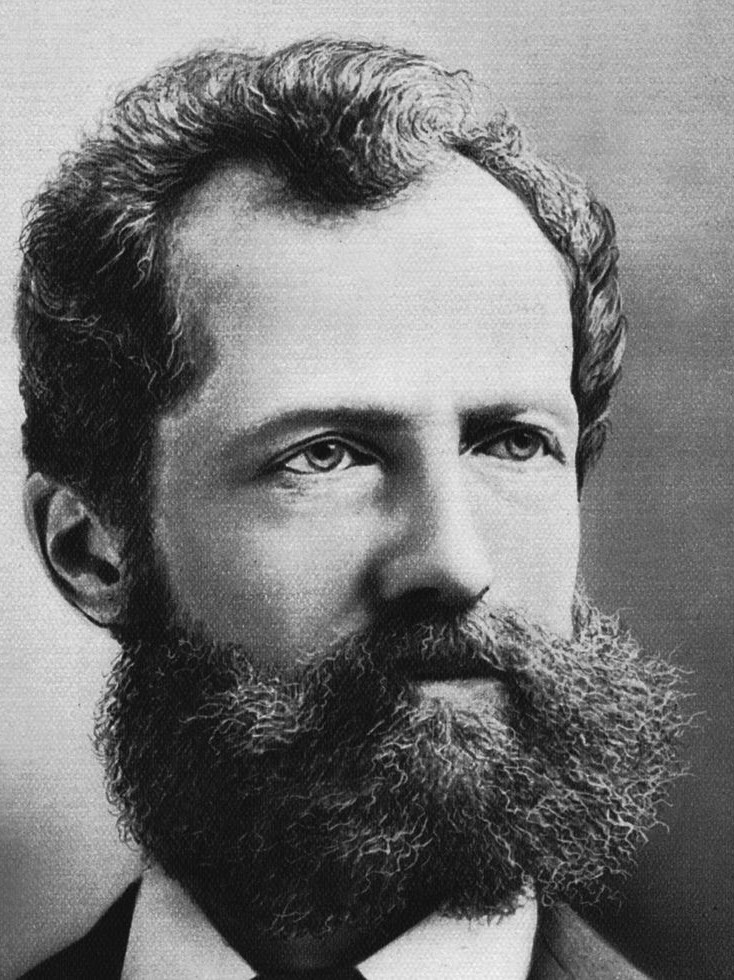

The Linotype machine was a revolutionary mechanical typesetting device that played a significant role in the history of printing and publishing newspapers, magazines, and books. Developed by German-American inventor Ottmar Mergenthaler, the Linotype Machine was first used commercially in 1886. It remained a key technology in the printing industry until the late 20th century when photo and digital typesetting took over.

The name of the machine comes from its ability of producing an entire line of types at once.

It was a significant improvement over the previous industry standard of letter-by-letter manual typesetting which was in use since the days of Johannes Gutenberg.

The linotype machine enabled much faster typesetting than had previously been possible. It was now possible for a typesetter to process up to 6,000 characters per hour. With later models, even up to 25,000 characters per hour were possible thanks to the use of punched tape technology.

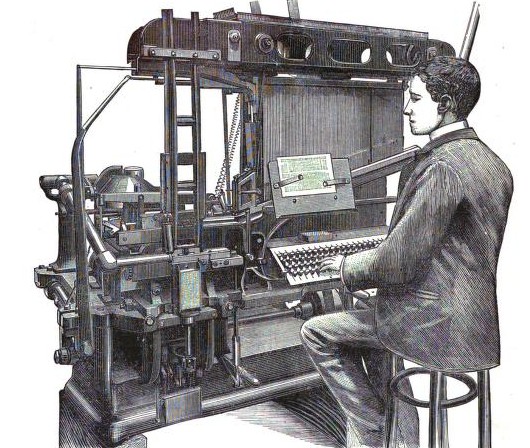

Mode of operation: The typesetter enters letters via a keyboard. The corresponding matrices are then automatically removed from the machine’s magazine and arranged into a line. Liquid lead is then used to create a metal line, which is inserted into the page grid of the print template. The metal lines are melted down again after the printing process and the matrices are returned to the magazine.

(1854–1899), the inventor of the Linotype machine

The Linotype machine soon began its triumphal march around the world, helping to satisfy the ever-increasing demand for print products. The machines were not only produced in the USA, but there were manufacturing locations in Great Britain and Germany, too. After just a few decades, its great success led to competing products (“Intertype” and “Linograph”), which largely made use of the original Linotype technology.

Over time, the Linotype machines were continuously improved, e.g. additional fonts and font sizes were implemented and new character sets for international use (Cyrillic, Arabic, etc.) were developed.

The end of the Linotype era did not come until the 1970s, when phototypesetting quickly replaced the now obsolete technology.

In the decades that followed, computer technologies made typesetting faster and more convenient. Since the 2010s, even fully automated typesetting is possible, which was developed by the DocAlign company. Text templates of all kinds are transformed into print-ready documents and other digital output channels with the touch of a button.

Technical aspects of the Linotype typesetting process

Matrix Assembly

When a key was pressed, a brass matrix for that letter or character would fall into place in a composing stick. The matrices contained raised characters on their faces.

Each matrix contains the letter form for a single character of a font of type, i.e., a particular type face in a particular size.

Magazine

The magazine section is the part of the machine where the matrices are held when not in use, and released as the operator touches keys on the keyboard. The magazine is a flat box with vertical separators that form “channels”, one channel for each character in the font.

Keyboard

By operating the keyboard, the matrices are fed into the composing stick.

On the Linotype keyboard, upper and lower case letters each have their own keys.

Molding

Molten metal, typically an alloy of lead, antimony, and tin, would be injected into the mold created by the assembled matrices.

Casting Mechanism

Once the metal solidified, it formed a solid line of type, known as a “slug.” This slug contained the entire line of text in a single piece.

The casting section receives completed lines from the assembler and uses these to cast the type slugs that are the product of the linotype machine. The casting section is automatic: once it is activated by the operator sending a completed line by raising the casting lever, a series cams and levers move the matrices through the casting section and control the sequence of steps that produce the slug.

Distribution Mechanism

After the typesetting line has been cast, the matrices are automatically returned to the correct place in the magazine.

This automatic return of the matrices did not exist before the Linotype machine was introduced.

The metal lines are melted down again after printing.